The hydraulic tensioning procedure is mainly used for highly stressed bolts with a thread range between M12 to M300.

This procedure enables the simultaneous torsion-free tightening of any number of bolts/screws with the same preload.

During hydraulic tensioning, the hydraulic unit is screwed onto the thread projection above the nut of the threaded bolt. Pressure is applied to the hydraulic unit, stretching the threaded bolt. This procedure lifts the nut away from the part being tensioned. The nut is then screwed down and the hydraulic pressure released. A defined tensioning force remains in the threaded bolt after the pressure is released.

Our range of hydraulic tensioners is very diverse.

The image shows some variants of our delivery program, for instance, hydro-tensioners with plunger thread, rotatable angular coupling and dial gauge (for checking the existing bolt elongation) and tensioners that can be used for various thread sizes with exchangeable tension nuts.

Example of a hydraulic ring unit that consists of 8 individual segments and designed for the simultaneous tightening of 32 threaded bolts M42 in the power station sector.

The hydraulic units are operated with a compressed air hydraulic pump (1500 bar).

Our delivery program includes compressed air and electro-hydraulic pumps (single and double-acting), in addition to hydraulic hand pumps, for various pressure ranges.

The image shows a compact compressed air hydraulic pump that can be adjusted up to 1500 bar. Particular technical features of this pump include 4 safety quick coupling halves SSK12 for the high pressure oil outlets, a glycerin-charged precision measuring manometer Ø 160 mm (accuracy class 1.0) and a particularly powerful plunger (pressure ratio 1:244).

We also have compressed air hydraulic pumps up to 7000 bar in our delivery program for oil pressure baudages.

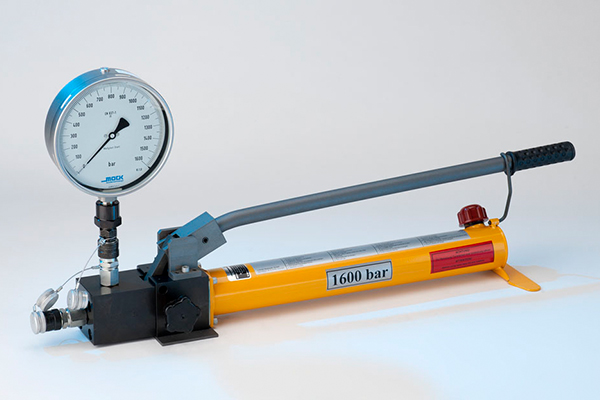

We offer hydraulic hand pumps for pressures ranging from 700 to 1500 bar.

Our hand pumps are available with permanent or detachable precision measuring manometers (Ø 100 mm or Ø 160 mm, accuracy class 1.0). They have up to 5 quick coupling halves SSK12 for the high pressure oil outlet.

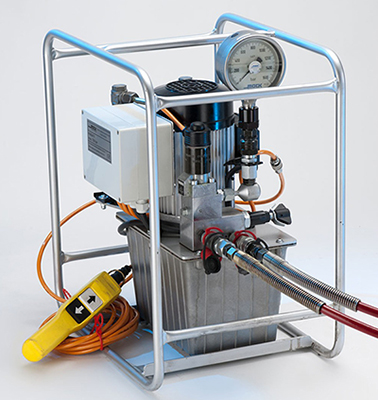

On request, we can produce special units, for instance, the synchronised pump shown in the image (electro-hydraulic unit).

This pump is used for balanced lifting and lowering of a complete bearing housing in the power station sector.

The hydraulic synchronisation of the connected hydraulic cylinder is ensured by a linear multi-chamber flow divider.

We also deliver electro-hydraulic pumps up to 1500 bar as an alternative to our compressed air hydraulic pumps.

The pump shown here is operated via a remote control (24V) with 5m connection cable.

Further equipment features of this pump include 2 safety quick coupling halves SSK12 for the high pressure oil outlet, a glycerin-charged precision measuring manometer Ø 100 mm (accuracy class 1.0) and a motor with an output of 1.5 KW (400 V, 50 Hz).

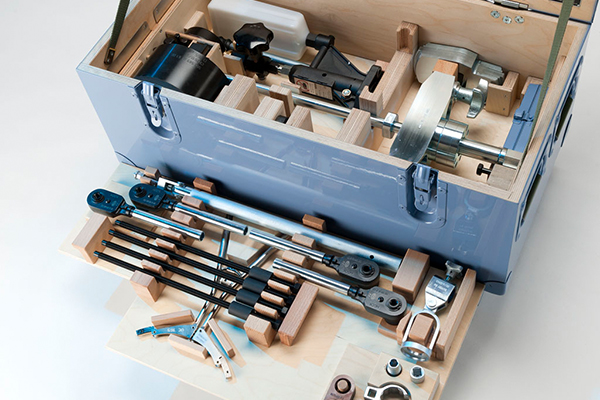

Our core business includes the production of special tools for large motors that we develop in close cooperation with the motor manufacturers.

These tools are used for the mass production, maintenance and repair of motors.

We deliver our tools as individual tools or in various combinations as tool sets.

Many of our tools are transported in specially designed and constructed wooden storage cases.

The particular features of these wooden cases include recessed hinges and handles, complete edge protection, corner protectors and many other features.

Special wooden inserts ensure that the tools arrive safely and undamaged at their destination.

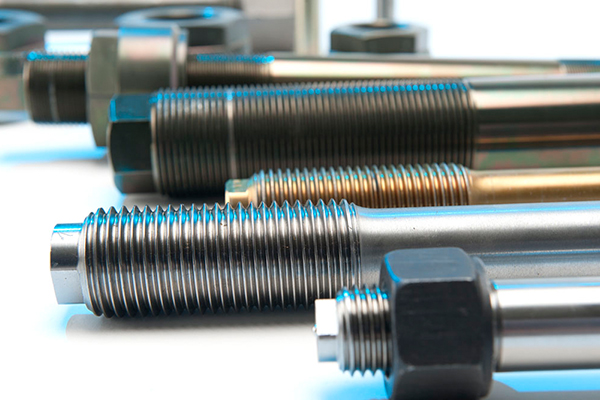

We have long-term experience in the sector of highly stressed threaded connections.

We develop and produce special bolts for your application cases.

We place great value on the selection of the material qualities and the production of the threads, which are usually rolled.

Our bolts are used in printing presses, power stations, steel works and forges, to name but a few examples.

In general, we produce bolts ranging from M12 to M130 together with the appropriate nuts, extension sleeves and washers.

The expansion bolts used for tensioning are often fitted with bores which can be used to hold a gauging pin. This gauging pin can be used to check whether the bolt elongation produced during tensioning is still present even after long usage.

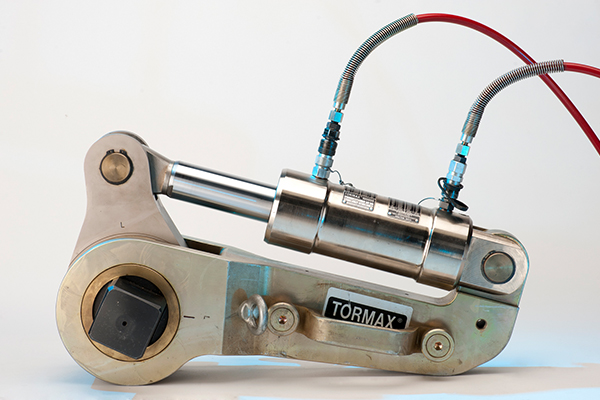

We have been developing and manufacturing our hydraulic wrench since 1980, marketing it under the registered trademark TORMAX®. Our wrenches are simple to use, durable and particularly suited for robust operations through the use of top material qualities. We have wrenches for torques between 3000 Nm to 100000 Nm in our product range. The wrench cylinders are designed for pressures up to 700 bar. Other pressure ranges are available on request. As our wrenches can be rapidly dismantled, they are extremely easy to maintain and service.

A large variety of wrench accessories such as jacks with various lengths, replacement square inserts, rotatable angular couplings, sockets in various sizes, etc. rounds off our wrench product range.

We also offer our customers wrench rental as a particular service.

The loosening and tightening of bolts can, on request, also be implemented by our qualified assembly personnel.